The milling of flour

Grinding stones are slabs of stone that Aboriginal people used to grind and crush different materials. Bulbs, berries, seeds, insects and many other things were ground between a large lower stone and a smaller upper stone.

Indigenous women in this region used stones like this to grind seeds from grasses, trees, shrubs and succulents to release the starch for cooking purposes. The flour produced was mixed with water and eaten as a paste or cooked in the coals of a campfire and eaten as cakes or loaves.

This stone is indicative of grinding stones used in this region for thousands of years.

It was found by the donor in the bed of the Greenough River.

The climate and soils of the Greenough Flats are ideal for growing wheat. From 1857, the land on the Front Flats was subdivided into agricultural blocks and sold to eager farmers. For a brief period this area was regarded as “the Granary of Western Australia” and two steam powered mills converted the wheat into flour.

After wheat is thoroughly cleaned, it passes through the mill where four main products are made:

- Flour: the centre of the grain containing endosperm.

- Bran: the outer layers of the wheat kernel.

- Pollard: the fine cell layer between bran layers and endosperm.

- Wheatgerm: reproductive layers.

The millers at Greenough produced two types of flour: –

- “Low grinding” was the unsifted flour from a single pass through the millstones. This flour had a 100% extraction, meaning it contained all parts of the original grain. This flour made dark hearty bread that retained all of the original nutrients of the grain.

- “20%” was flour that had been reground several times and sifted extensively to remove the bran.

- The bran and pollard were used to feed livestock.

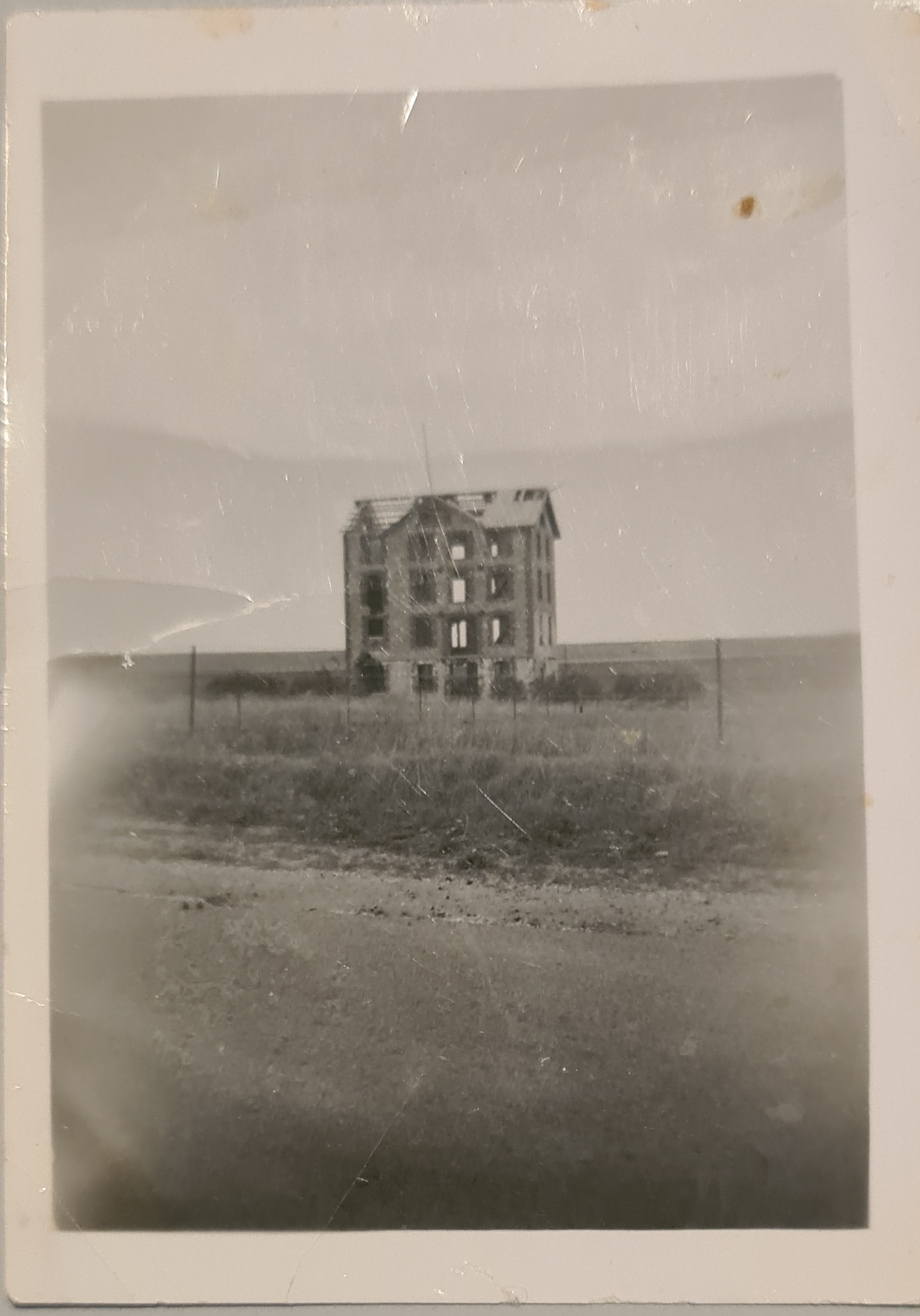

Construction of a steam-powered flour mill for Walter Padbury at Central Greenough commenced in 1857.

The mill was sold to Thomas Clinch in 1868 who made alterations soon after purchase. In 1889, Clinch imported roller mill technology, possibly in anticipation of increased business due to the closure of nearby Maley’s Mill. The new machinery began operations in 1891 in the new three storey structure and continued operations until 1927. The machinery was removed in 1934.

The building is currently owned by the National Trust of Australia (WA).

Photograph taken c1940 by a member of the Knapp family. Donated by Marie Zinetti 2018/022.

In 1860 John Stephen Maley arrived at Greenough and built the district’s second steam mill on 50 acres of land at North Greenough owned by George Shenton. Built by Edward Willis, Maley’s Mill traded as the Victoria Flour Mill and the first silk dressing machinery to be used in the colony was installed in 1872. The mill ceased operating in 1891.

The building and surrounding farm was sold to the Rudduck family in 1932 and they used the mill as a shearing shed and for storage. The three storey mill was destroyed by fire in 2013.

The ruin is privately owned.

Photograph taken by Joe Glass c1985. Donated by Barbara Sheilds 2008/052.

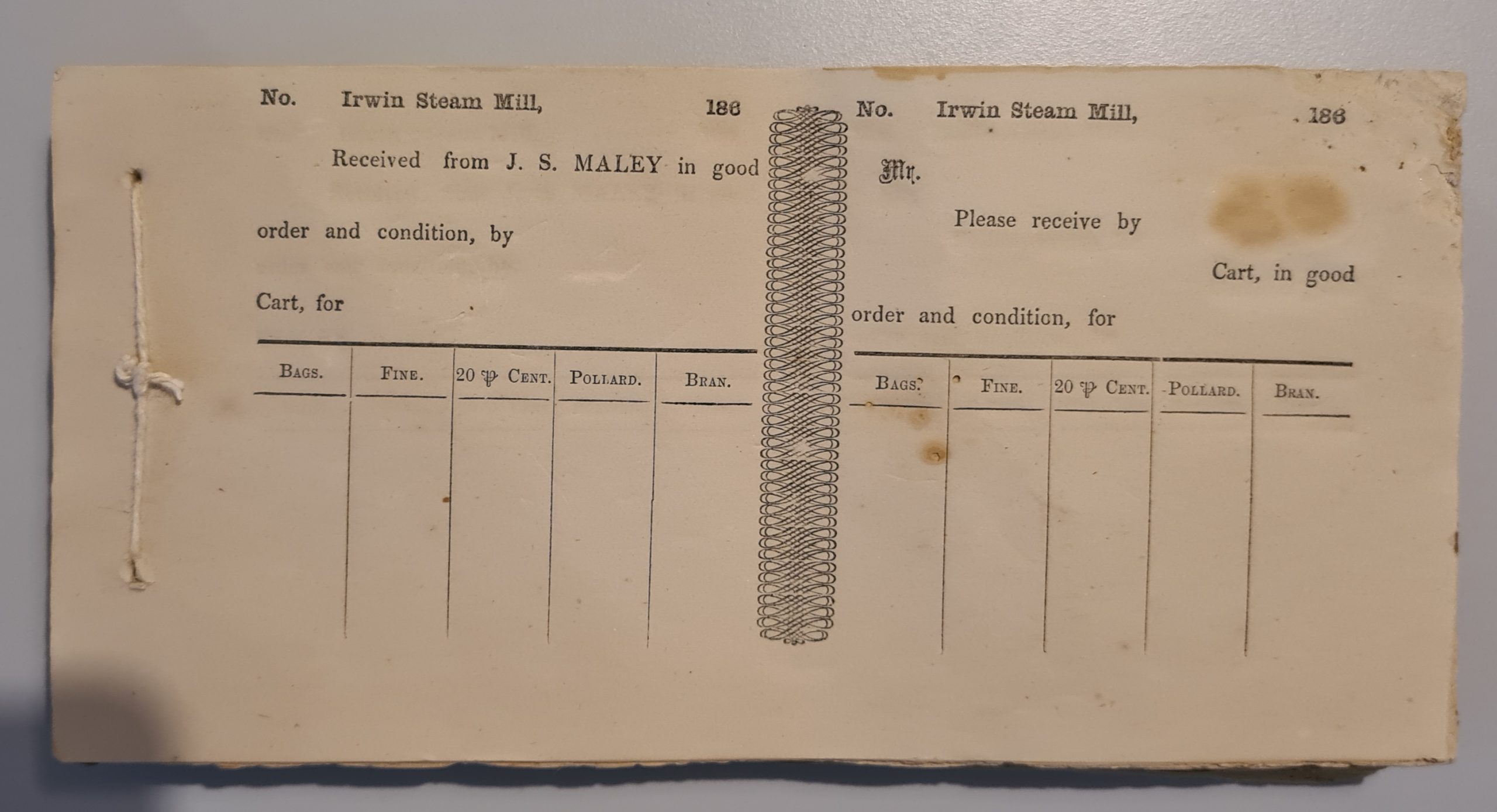

Left: The first docket book used at Maley’s Mill, contains stubs for docket nos.1-264, dated 1/04/1861 to 24/02/1862.

Contains information on amount of wheat delivered, who it belonged to and the carter’s signature.

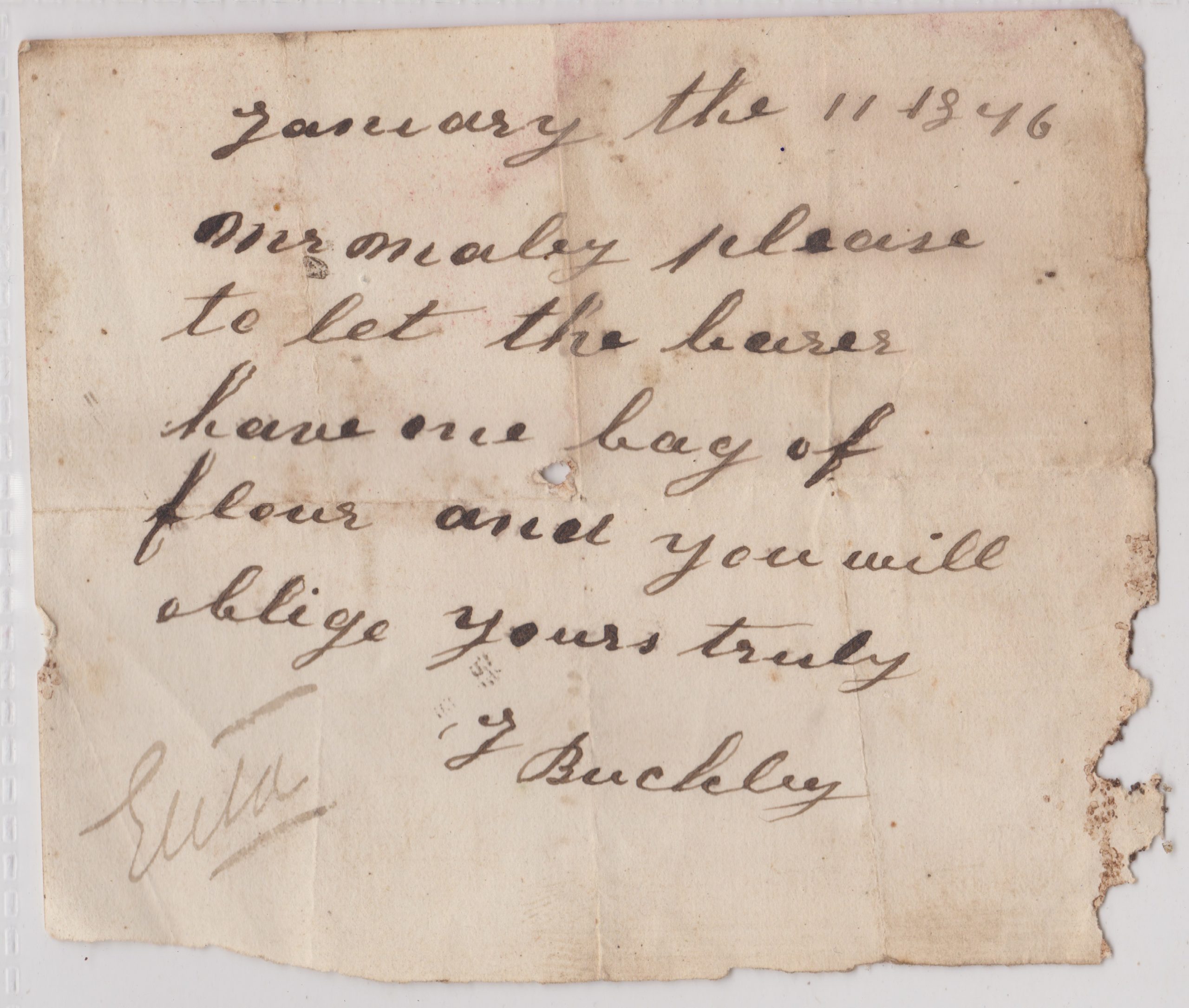

Right: order for flour from J. Buckley

january the 11 1876

mr maley please to let the bearer have one bag of flour and you will oblige yours truly

J Buckley

The Irwin Steam Mill was built at Dongara on the banks of the Irwin River by John Smith and John Maley in 1865. The mill went into decline after shipping stopped calling at the port due to bad anchorage and was closed in 1894. It was later demolished.

Unused Irwin Steam Mill receival book from the Maley Mill & Store Archives 1966/1701.

Francis Pearse built the Royal Steam Roller Flour Mill at Dongara in 1894. Powered by huge steam engines, the mill ground wheat produced in the district until its closure in 1935. The mill had a large floor space and receiving sheds capable of holding 8,000 bags of wheat. Flour milled here was shipped to the north west or freighted south by the Midland Railway. The mill was capable of producing six tons of flour per working day, at a rate of about seven to eight sacks per hour.

During World War II the mill was used as an army camp; much of the timber was removed to be used for gun emplacements and a rifle range in the coastal dunes. With the shortage of materials, much of the internal timbers were also removed following the war.

Photograph taken in June 1959 by Cecil Maley. Donated by Fay McKinnon 2015/037.

The Victoria District Flour Milling Company commenced operating on a block of land bordering Chapman Road and Phelps Street, Geraldton in 1910.

In 1923 the Victoria District Flour Mill purchased the Dongara Flour Mill and its machinery was moved to the Geraldton site.

The business went into liquidation in 1958, but the WA Government stepped in to save the workers’ jobs and the mill was leased to the Peerless Milling Company of Guildford in 1961.

The mill was closed, machinery destroyed, and the buildings demolished in 1976.

Victoria District Flour Milling Co flour bag c1950. Anonymous donor 2013/167.